When do leaf springs need to be replaced?

Updated: September 25, 2022

Leaf springs were widely used in cars until the late 1970's. Today you can find them in classic cars as well as in the rear suspension of many pickup trucks and vans.

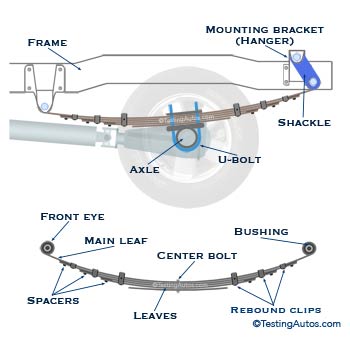

Some vehicles use mono-leaf springs, while most pickup trucks have multi-leaf rear springs, as they

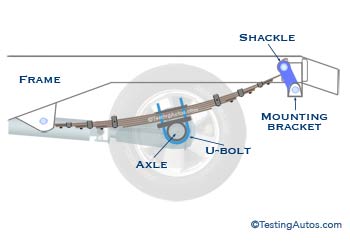

are better suited for heavy loads.Leaf springs not only support the load, but hold the rear axle in place. In a typical pickup truck, leaf springs are directional; there is only one way to install them. The front end of the leaf spring is connected to the mounting bracket attached to the frame.

The axle is located to the leaf spring center bolt and secured by U-bolts. The rear eye of the leaf spring is connected to the frame through a shackle that can swing back and forth, allowing for spring expansion. In some trucks, shackles are installed below the rear mounting brackets (hangers); in others above.

Leaf springs can last long; we have seen many old trucks that still had original leaf springs. However, problems related to leaf springs are common. One of the possible signs of a problem is when the rear of the truck is sagging or the truck leans to one side. When this happens, the headlights can also point higher, blinding drivers in oncoming vehicles.

Sagging leaf springs can be caught when doing the wheel alignment. In some cases, a broken leaf spring can cause a knocking or rattling noise.

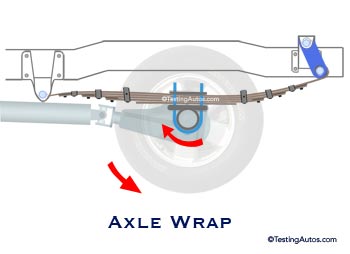

Another reason to replace leaf springs is when they become weak and cause axle wrap where the axle twists back and forth. Leaf springs are also known to produce squeaking noises when driving over bumps; read this post: Squeaking leaf springs: causes, repair options

Leaf spring problems: Leaf springs can sag and weaken or one of the leaves can crack, fracture or break.

In some trucks, replacing leaf springs is fairly easy, although bolts are often seized; in others, the fuel tank or some other part is in the way and might need to be removed or lowered. If you are doing the job yourself, make sure to follow the manufacturer's instructions and safety precautions. If you use your truck for hauling heavy loads, you might opt for upgrading to heavy-duty leaf springs, although they are more expensive and will cause a stiffer ride.

The broken leaf is a safety concern. A fractured or broken piece of a leaf spring can damage other parts or jam under. It can also fly off and create a hazardous situation for other motorists and pedestrians. If a leaf spring is broken, check for warranty extensions or recalls. For example, Toyota recalled certain 2005-2011 Tacoma Pre-Runner and 4x4 Tacoma models for possible leaf spring fracture (Safety Recall E02, NHTSA Campaign Number: 14V604000). GM issued leaf spring coverage extension for the 2008-2009 Chevrolet Silverado, GMC Sierra LD in certain Northeast states and parts of Canada (Service bulletin 14520A).

Can you replace just one leaf? Usually when one of the leaves breaks, both leaf springs are replaced. It's technically possible to replace only the broken leaf, but often when one leaf breaks, other leaves might be worn-out, cracked or fatigued. It's also not always easy to find a separate leaf that fits your truck, although a local spring repair shop can help.

Many problems related to leaf springs are caused by faulty leaf spring hardware. For example, a rear shackle hanger is known to rust and break off in some trucks. It will also cause one of the sides to sit lower. Although the part is not very expensive, replacing a broken hanger (bracket) can be labor-intensive, but most shops offer a reasonable price for this kind of job.

Because leaf springs locate the rear axle and maintain a proper driveline angle, problems with leaf springs or hardware can affect the directional stability of the truck and cause clunking or driveline vibration. For example, worn-out leaf spring bushings can cause the axle to shift back and forth or the angle between the axle and the frame to change when driving over bumps.

Leaf spring bushings are not very expensive, but it might take quite a bit of labor to press the old bushings out and new ones in. Weak leaf springs can twist, causing a change in the driveline angle (axle wrap), which often results in driveline vibrations felt during hard acceleration or when decelerating at 10-30 mph.

Some manufacturers offer tapered shims for the leaf springs to correct the driveline angle, others recommend replacing weak leaf springs. Many truck enthusiasts install aftermarket traction bars that limit the rotation of the axle.

Loose U-bolts or a broken centre bolt can also cause the axle to shift from its place resulting in similar problems. For example, GM service bulletin 09-03-09-001G for the 2007-2017 Chevrolet Silverado and several other trucks describes a clunking noise coming from the rear of the vehicle that can be caused by loose U-bolts.

Advertisement

Leaf spring maintenance: Leaf springs don't need any maintenance, but they need to be regularly inspected with the truck lifted on a hoist for signs of wear or damage (e.g. cracks, fractures, wear marks, splits) as well as for loose U-bolts and other joints. If new leaf springs are installed, it's a good idea to re-torque U-bolts during the next service. Some manufacturers recommend pressure-washing leaf springs after driving on unpaved roads to avoid squeaking. Read more: Squeaking leaf springs: causes, repair options