When do the control arms need to be replaced?

Updated: March 12, 2020

Control arms in a car are vital parts of the front suspension. If a control arm is worn out or damaged beyond what a car manufacturer considers acceptable, the vehicle is deemed unsafe to drive.

In recent years, the quality of front end parts, including control arms, has improved, but they still fail.

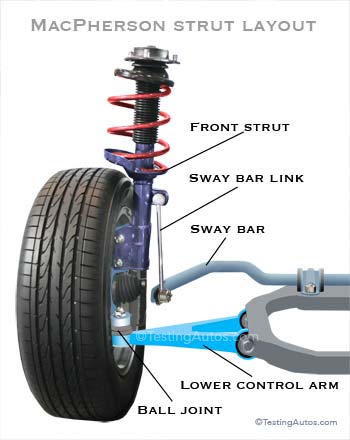

Even some modern electric cars have problems with control arms and other front end parts, so local auto repair shops won't go out of business anytime soon. How a control arm works: In the front suspension design with MacPherson struts common in modern cars, there is one "lower" control arm on each side, see the illustration. The inner side of the arm is attached to the subframe or body via rubber bushings to dampen road noise and vibration. The bushings provide pivot points, allowing the control arm to swing up and down as the vehicle drives over bumps.

The outer end of the control arm connects through a ball joint to the steering knuckle, the part that carries the front wheel. A stabilizer (sway) bar connected to both lower control arms or struts keeps the car stable in turns. See this illustration of the front suspension.

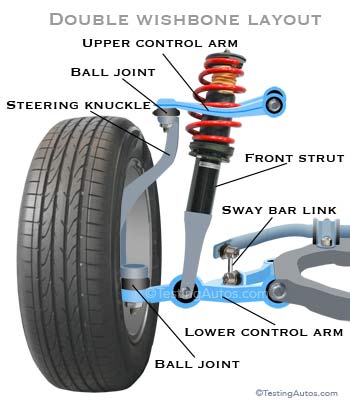

In a double-wishbone ("double A-arms") layout (in the image), the steering knuckle is held by two, lower and upper control arms. A double wishbone layout is used in many pickup trucks, large SUVs, many high-end vehicles and race cars. The upper control arm is smaller. The larger lower control arm carries most of the load. Both the lower and upper control arms have a ball joint, although the upper ball joint is often smaller. As the wheel drives over a bump, both arms swing up and down on rubber bushings following the wheel.

In either layout, control arms are very important components. If a control arm fails, the safety of the vehicle is compromised.

If a control arm needs to be replaced, especially if it happens soon after the warranty has expired, check with a local dealer if it there is a recall or extended warranty, as it's a safety item. In recent years, several car manufacturers have issued service campaigns, warranty extensions or recalls to cover failed or rusted control arms. Even if it's not covered, and you have to pay for the repairs, keep the receipt. If there is a recall in the future, there is a chance that a manufacturer might offer a reimbursement.

There are several reasons why a control arm needs to be replaced. The most common reason is when a ball joint wears out, and it cannot be replaced separately. Often a ball joint comes with a control arm as one unit.

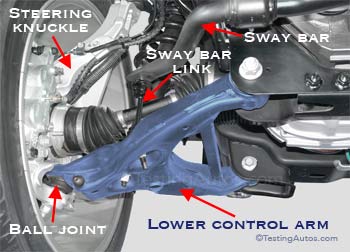

Lower control arm of the Ford F-150 pickup truck. See also: Toyota control arm.

Lower control arm of the Ford F-150 pickup truck. See also: Toyota control arm.Worn-out or cracked control arm bushings is another reason to replace a control arm, although in many cars, the bushings can be replaced separately. See this photo of control arm bushings. Another reason to replace a control arm is when it has been damaged or bent after hitting a pothole or curb.

The choice of whether to replace only a ball joint or bushings or the entire control arm often depends on the price, the overall condition of the arm and part availability. What is more cost-effective?

Advertisement

After a control arm is replaced, in most cases, the wheel alignment needs to be performed to bring the steering and suspension angles back to within the specifications. It is not necessary to replace both lower or both upper control arms if one is bad, but often they wear out at roughly the same mileage. If one control arm is bad and the other is on its way, it makes sense to replace both arms at once. This way, you only need to do the wheel alignment once. The key question to ask your mechanic when deciding on repair options is "will my car be safe to drive?"

Read Next:

When should struts and shock absorbers be replaced?

When does the tie rod end need to be replaced?

When do the ball joints need to be replaced?

When to replace sway bar links?

When do coil springs need replacing in a car?

How often should the wheel alignment be done?

When Should Tires be Replaced in a Car?

When should struts and shock absorbers be replaced?

When does the tie rod end need to be replaced?

When do the ball joints need to be replaced?

When to replace sway bar links?

When do coil springs need replacing in a car?

How often should the wheel alignment be done?

When Should Tires be Replaced in a Car?