Updated: April 22, 2020

What makes Nissan GT-R so fast – technology explained

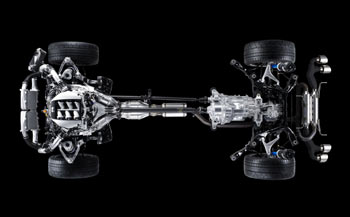

The Nissan GT-R is fast thanks to what Nissan calls the Premium Midship platform, with a rear-placed transaxle and a lightweight but very powerful twin-turbo V6 engine in the front. Together with all-wheel drive, this platform creates a perfectly-balanced performance machine with excellent grip on all four wheels, allowing for excellent acceleration, speed and control. The Nissan GT-R is the least expensive supercar you can get. The GT-R is a street-legal coupe with a V6 engine, yet it can accelerate from 0 to 60 mph in under 3 seconds.In a conventional rear-wheel drive sports car, like the Chevrolet Camaro, Ford Mustang or Toyota Supra, the engine and transmission are placed in the front, but the engine torque is sent to the rear wheels.

Nissan GT-R. Photo: Nissan.

Nissan GT-R. Photo: Nissan.This is what Nissan engineers designing the GT-R took into account. The GT-R is all about grip. It has an all-wheel drive, meaning the engine power is delivered to all four wheels. The engine is positioned in the front. The transmission, combined with the transfer case and a rear differential in one unit, is placed in the back. This gives the GT-R a near perfect weight distribution 53/47 front to rear. What's more important, each wheel is pushed to the road at roughly the same weight.

Nissan GT-R all-wheel drive system is a rear-biased all-wheel drive system, meaning the rear wheels are always powered, receiving 50-100% of engine torque depending on the driving conditions. When needed, up to 50% of torque can be sent to the front wheels. Let's look at the power flow in this diagram provided by Nissan: the engine torque is sent to the transaxle unit located at the back through the main carbon-composite propeller shaft (the larger shaft in the middle). The transaxle unit has a built-in transfer case, a device that splits power between the front and rear axles. Click on the photo to see the larger image.

The smaller additional propeller shaft sends the torque from the transfer case to the front differential. The front differential splits the torque between the left and right front wheels. The rear differential is built inside the transaxle unit. The amount of torque sent to the front axle is controlled by the electronic control module using a multi-disc hydraulic clutch installed in the transfer case. The torque split between front and rear axles varies depending on the road conditions. For example, under heavy acceleration, the torque is split close to 50:50 front to rear, but when coasting on a dry road at a steady speed, almost all power is sent to the rear wheels.

VR38DETT engine

The Nissan GT-R has a twin-turbo 3.8L V6 VR38DETT engine. It uses some of the valve train components and basic design of the well-known VQ35 motor that has been used in many Nissan models such as the Altima, Maxima and Pathfinder. In the VQ engine, the cylinders are made of cast iron sleeves pressed into the aluminum block. This is done to make the cylinder walls stronger to withstand up and down piston movement. To make the VR38 lighter, instead of heavy cast iron sleeves, a very thin layer (0.15 mm) of hard metal is applied to the cylinders using the plasma spray process. How the plasma spray process works: the stream of inert gas mixed with the powder of the coating material is heated using an electric arc and sprayed onto the cylinder walls.Weight distribution is very important for any sports car. Instead of opting for a larger V8 or V10 engine, which would make it front-heavy, the Nissan GT-R uses a lighter V6 motor with two high-performance IHI turbochargers.

Nissan GT-R turbochargers.

Nissan GT-R turbochargers.The 3.8L V6 VR38 twin-turbo engine in the 2014 Nissan GT-R is rated at 545 horsepower at 6,400 rpm. The VR38DETT has a twin-cam design (each cylinder head has two camshafts), with four valves per cylinder. A variable timing system is used on the intake side. The intake camshafts are driven by a timing chain that is hidden behind the front engine cover.

6-speed dual clutch automated manual transaxle

The Nissan GT-R uses a 6-speed dual-clutch automated manual transmission produced by BorgWarner, which is essentially a manual transmission controlled by a computer. The transmission also has a 'Manual' mode that allows the driver to shift gears using paddle shifters mounted on the steering wheel.To understand how a dual-clutch automated manual transmission works, let's refresh how a regular manual transmission operates: you press the clutch, engage the first gear, then release the clutch; the steps are repeated with every shift. A dual-clutch automated manual transmission has two wet computer-controlled clutches ("wet" clutch means the friction plates are immersed in transmission fluid). One clutch controls odd gears (1,3,5); the other clutch controls even gears (2,4,6).

Brakes, wheels and tires

The Nissan GT-R uses Brembo six-piston brakes with full-floating vented and drilled two-piece rotors in the front. Six pistons means this caliper in the photo has three pistons on each side of the rotor. Pistons are pushed out with hydraulic pressure to squeeze the rotors while braking. For comparison, a typical front-wheel drive car has only one piston on the inner side of the caliper. The front rotors in the 2014 Nissan GT-R are 15.35 inches in diameter, much larger than in regular cars; for example, the front rotors in the 2013 Nissan Altima are only 11.7 inches in diameter.The rear brakes in the GT-R have a similar design, but with 4-piston calipers and smaller 15.0-inch full-floating two-piece rotors. 'Full-floating' means that the outer cross-drilled disc is connected to the inner part or 'hat' with a special hardware that allows some flex. This helps prevent warping, as the outer disc can expand separately from the 'hat' when heated.

Knurling on the rims.

Knurling on the rims.